Engineering Facilities

Delve into the heart of innovation and explore our state-of-the-art Engineering labs and workshops that empower you to push boundaries. Our facilities drive hands-on learning and groundbreaking research. Take a closer look and witness the future of engineering education and discovery.

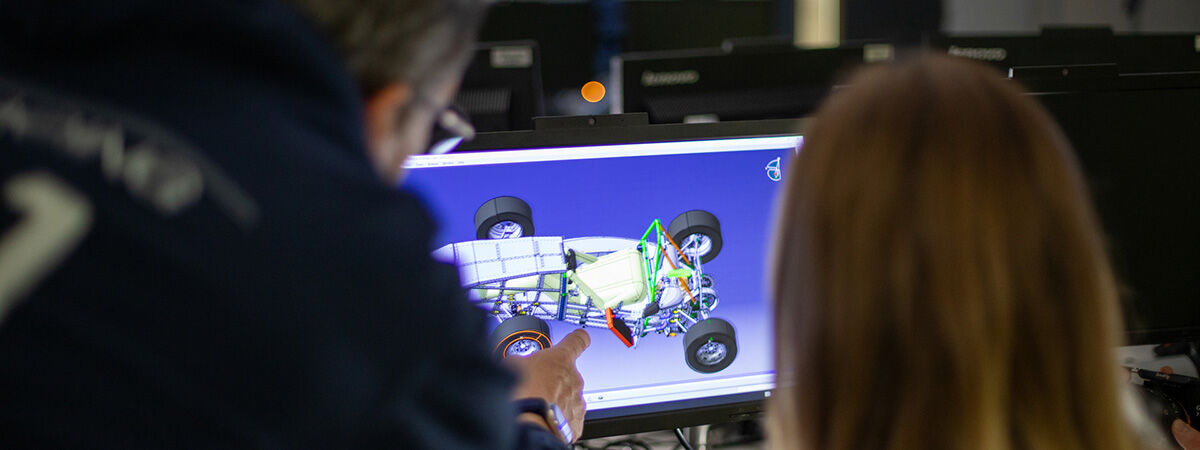

CAD and Programming Labs

Our Computer Aided Design (CAD) and Programming labs allow you to create your own 3D designs and simulations and test how they would perform in the real world by applying theoretical loads to them. You can also design and test electronic circuits, generate AI designs and program software for embedded systems (Raspberry Pi and Ardunio). Students have used these facilities for reverse engineering of PlayStations, designing rollercoasters and designing and simulating racing cars.

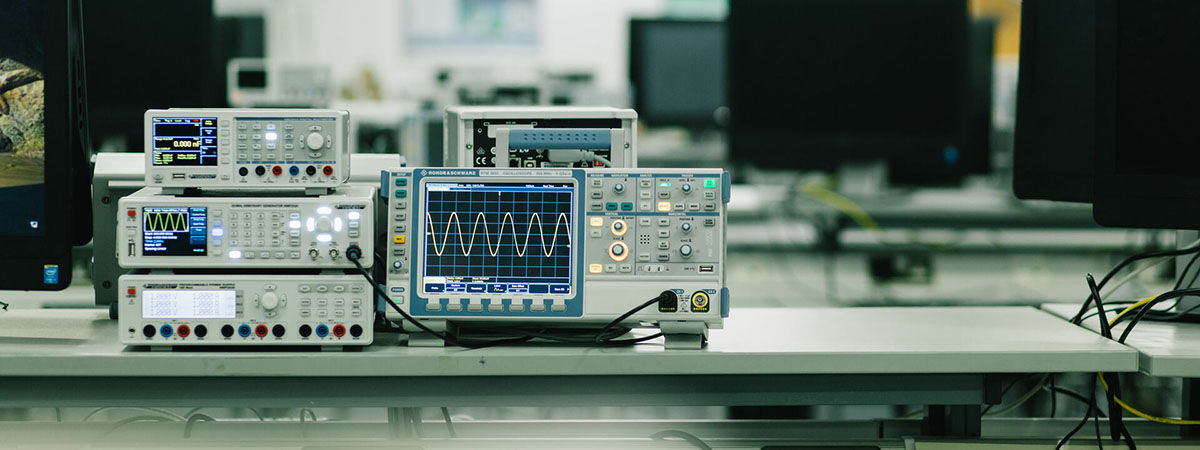

Electronics Lab

Our Electronics Lab hosts professional test equipment including oscilloscopes, signal generators, multimeters and power supplies to build and test electronic systems and projects. Previous students have used these facilities to create robots and drones as well as build computers, micro-controllers and wearable tech. Our Electronics Lab is also where our Repair Lab is held, where students can get hands-on repairing broken appliances and gadgets.

Civil and Bio-Engineering Labs

In these labs, we are interested in exploring how engineering can be applied to improve the built and natural environment, including looking at factors such as sustainable construction materials, recyclability, natural resources (energy, water, land use) and the effects of pollution.

Mechanical and Hydraulics Labs

In these labs you can explore different physical and material properties which help to explain fundamental engineering principles that can be applied across all engineering disciplines. They have a range of test equipment, where you can analyse the performance of the materials in the real world compared to simulated data.

Workshop Space

This is an area containing CNC machinery. These are automated computerised manufacturing machines used to produce parts, typically from metal or wood. There are also benches for assembly work using hand tools and equipment. In this space, you will learn how mechanical systems, such as two-stroke engines, work. Past students have built pneumatic piston engines and motorbikes and worked on household appliances and welding.

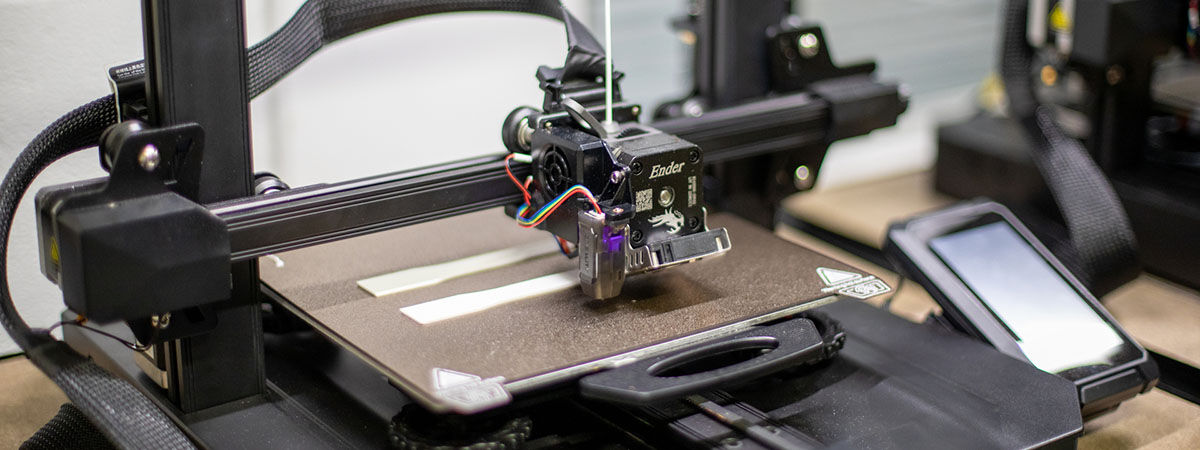

3D Printing Lab

This lab contains machinery used to print 3D components and objects in materials such as resin, plastics and metals (titanium, aluminium and steel). These would typically be parts or assemblies for projects or research. Within half an hour, you can turn a model from a computer screen in to a real, physical model.

Formula Student Lab

This lab contains a workshop used to build racing cars and experiment with automotive systems including body electronics, engine management, chassis dynamics. The workshop contains cars that you are able to experiment on with various testing. You can also join the BCU Racing Society, which takes part in the Formula Student challenge every year, where students work on designing and building a car that could be raced at Silverstone.

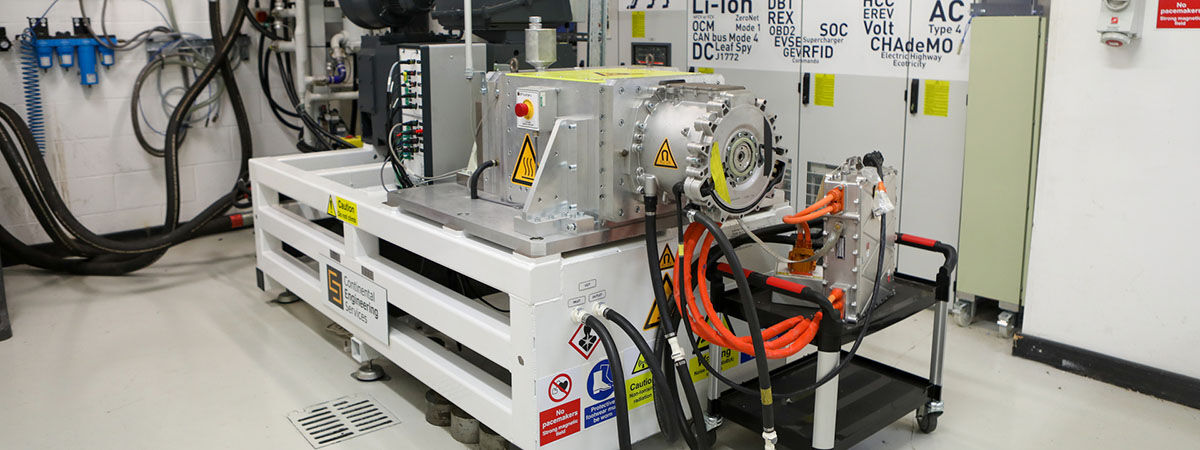

Electronic Vehicle (EV) Test Lab

This is a facility for testing electric vehicles, where students can analyse the performance of electric motors and battery systems and understand how these can be optimised and developed – this is essential if you are looking to go into a career in automotive engineering.

Greater Birmingham and Solihull Institute of Technology

Students across our Engineering and Computing courses automatically become Institute of Technology Learners and can take advantage of the facilities and opportunities provided by the Greater Birmingham and Solihull Institute of Technology (GBSIoT).