To produce a safe and efficient manufacture and assembly of a DfMA house, there are three main considerations. This includes the following: (i) Fixing the C-beams (ii) Panel Handling and (iii) Tooling Pallet. Through the use of lean and agile knowledge, best solutions are adopted to assist the production line, reduce overall process time, ensure higher quality assurance and deliver real value. All solutions proposed below enables batch production of DfMA frames along a linear process, to achieve enhanced productivity and total client satisfaction.

1) Panel Assembly for fixing the C-beams

QM System Ltd have conducted examination of several methods for fixing the C-beams of the DfMA house. The following methods are: Self-pierce riveting, Welding, Clinching and Screw insertion. The process of welding was avoided due to health and safety concerns and high cost expenditure. Cutting through galvanised steel releases toxic emissions of zinc oxide, which is poisonous and correlates to serious health impairments (i.e. lung diseases, reduction in breathing capacity, dizziness, metal fume fever, etc). Therefore, costs are expended as a dust fume extraction is required, along with a surface treatment to prevent oxidisation and exposure to zinc oxide. Moreover, zinc oxide can make weld penetration difficult, which can potentially increase the production process and running costs to manufacture a DfMA frame, thus undermining the total benefits of adopting a welding method.

Similarly, the self-pierce riveting mechanical fastening process is avoided because it undermines a lean production process. This method drives a rivet through frames and interlocks them using a suitable die. However, this method was dismissed for the DfMA production line as the efficiency is heavily reliant on a large work force of labourers. High manpower is equivalent to greater costs and increased energy expenditure, which can potentially lead to a low aesthetic finish and add extra weight to the DfMA, hindering the efficiency and overall production process.

Of the remaining methods, clinching was viewed as an optimistic method to fix the C-beams due to several reasons; 1) the method does not involve feeding of a secondary part to form a primary joint; 2) no additional material or rivets are needed, thus reducing production complexity; 3) the method is a more economically viable investment compared to other methods (i.e. self-pierce riveting, welding, etc); 4) maintenance requirement is comparatively low after the initial capital investment.

Before the clinching concept could be taken any further, it is concluded using screw insertion is the best way forward to assemble the frames. The decision was predominantly based on the concept that screw insertion does not give a permanent joint unlike all the other aforementioned methods. Screws are manually inserted through self-drilling or automatically fed to the frame, enabling two screw cycles at once. This makes it a convenient, cost-effective and smart approach to re-work joints when there are faulty screws or errors in the final assembly. The screwing requirements are uniform across all stations, thus optimising production systems and lower design costs.

2) Panel Handling

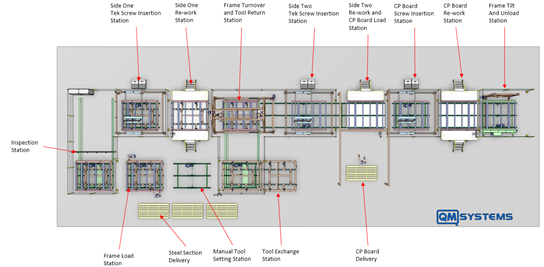

QM system Ltd have proposed specialised grippers to handle panels during the production process. Fundamentally, the panel is gripped by a series of pneumatic toggle grippers because of its high-strength gripping force, which enables panels to be securely lifted and turned over during the screw insertion processes. Screw jacks are suitable for lifting high loads and high duty cycles, mechanically linked to each other to allow safe operation. Furthermore, slew drives are mounted to the grippers to allow controlled rotational motions of the panel, whilst minimising health and safety risks. The grippers have an adjustable width to account for variability in panel lengths and styles, thus increasing line flexibility and ease of manufacture of DfMA frames.

Finally, to unload the panels at the end of the line, a solution to lift the panels was proposed to one side using screw jacks in a mechanically simple and space efficient A-frame lifter. Once they are aligned in a vertical position, they are stored in a toast-rack style storage unit, ready to be delivered to construction sites.

3) Tooling Pallet

The tooling pallet has been designed with both movable and fixed clamps (Figure 3) that allows customisation. Flexible tooling pallet is established, comprising many movable clamps to secure the C-section beams to form a frame for panels. The clamps are around 400mm tall to compliment the clinching process and allow the clinching tool to pass underneath to fix beams together during the production process. The flexible tooling pallet accounts for variability in panel designs as each clamp on can move along a linear rail as per client requirement and interests. Ultimately, the tooling pallet is designed with high resilience and strength, which enables it to hold beams in the correct positions until they are successfully clinched. This increases the speed of the manufacture and production process, boosting efficiencies and quality assurance.

The adjustment feature of the tooling design accommodates for various panels with numerous features (i.e. doorways or windows or slanted panels for roofs details, etc) and dimensions. This has resulted in a tooling pallet design which can carefully handle panels for screw insertion on both sides at a low cost.

Figure 3: Fixed Tooling, Flexible Tooling Pallet with movable clamps and Tooling Pallet with both movable and fixed clamps developed for Screw Insertion (Source: QM Systems: Modular Housing Assembly Line, 2020)