Birmingham City University have developed a Knowledge Based Engineering (KBE) tool to estimate life cycle cost and CO2 emissions estimations in real time for DfMA houses.

Research background

The use of KBE was proposed to address the issue of lacking modular production knowledge, scalable product solutions and holistic evaluation tools.

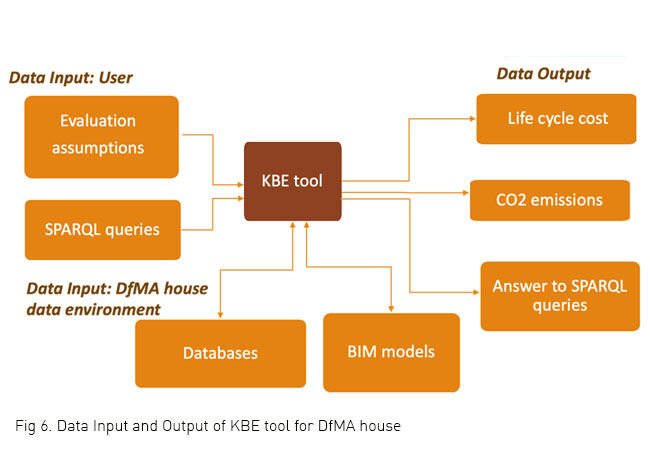

The KBE tool development serves two main purposes. First, it systemises the knowledge required for life cycle cost and CO2 emissions estimations in terms of their purpose, data source, concepts, model type, and relationships. Second, the KBE tool attempts to link data from different sources and facilitate life cycle cost and CO2 emissions for projects comprising DfMA houses. As the production knowledge of DfMA house is programmed in the tool, users can also probe the process and product information such as activities duration within a production process or transportation routes, in appraising DfMA house design.

Scope of life cycle cost and CO2 emissions estimation

The KBE tool estimates life cycle costs and CO2 emissions by capturing and modelling activity, product, resource, cost, CO2 emissions and geometric data associated with the life cycle of DfMA houses, comprising the design, manufacture and assembly, and 60-year period in-use stages. The scope of the tool include:

- Give overall and breakdown estimates of life cycle cost to be displayed in a user-friendly web-based interface

- Give overall and breakdown estimates of CO2 emissions to be displayed in a user-friendly web-based interface

- Give answers for semantic-based queries

BCU team, comprising multidisciplinary experts have developed a proof-of-concept KBE tool to allow users to process and extract life cycle cost information and CO2 emissions of a DfMA house. Key Researchers include:

- Walsall Housing Group (whg) - one the largest providers of affordable and high-quality homes across the West Midlands region. They define the user requirements for the project.

- Hadley Group - a world-class engineering leader in cold rollforming technologies, specialise in producing light-weighted steel components, with exemplary fire resistance ratings and acoustic entrapment. They design the steel framework for the DfMA house.

- Northmill Associates - a design-led architectural firm, offering robust, client focused advice and building solutions. They lead the development of DfMA house design.

- QM systems - an innovative solution provider of automated test systems for production lines, robotics and bespoke engineering development. They evaluate the automation potential in the design for manufacture.

- Energy Systems Catapult (ESC) - a dedicated team of qualified engineers with a mission to unleash innovative solutions to decarbonise society and capture opportunities to minimise the ecological footprint. They assess the energy performance of DfMA house design.

Hierarchy and Boundary of Life Cycle Costs and CO2 emissions

Life cycle cost model explained

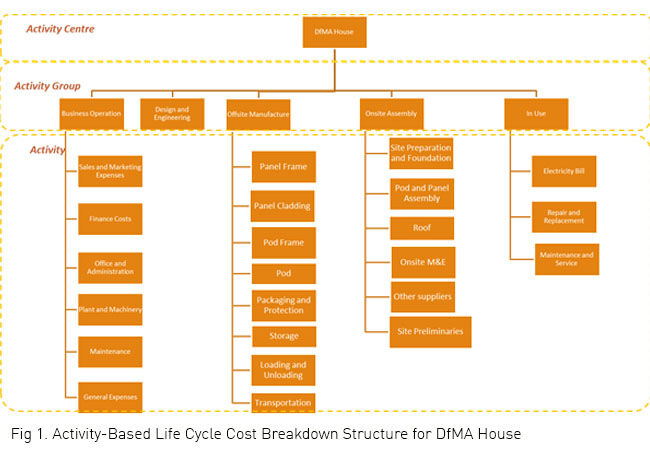

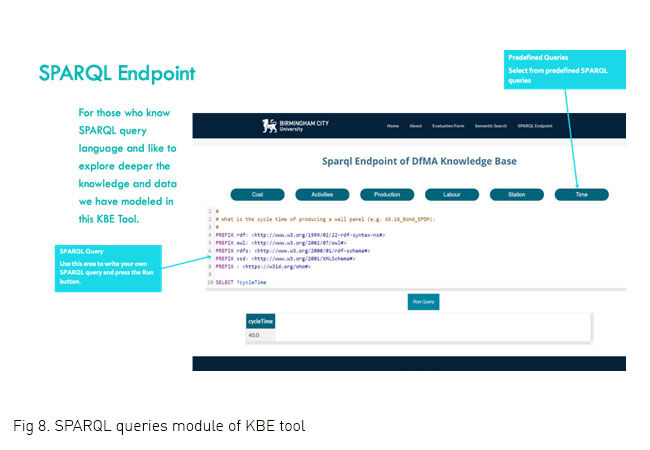

The KBE tool provides an overall and breakdown of life cycle cost estimations of a DfMA house. The life cycle cost is broken down to a hierarchy of 5 levels outlining all activities, associating sub- activities and their resources required (See Figures 1 and 2).

The life cycle cost model for DfMA house comprises the following:

- Business operation such as finance, marketing, administration and property management

- Professional fees for design development

- Construction costs for substructure and superstructure elements, including furnishing, fittings, building services, builder’s work in connection, external work, site preliminaries and main contractor’s profits

- Operational costs of major future repair and replacement works, regular maintenance works, and electricity bills over a period of 60 years

The life cycle cost model excludes taxation, land cost, future user’s finishing, water bills, occupancy cost such as TV licence, demolition and disposal costs.

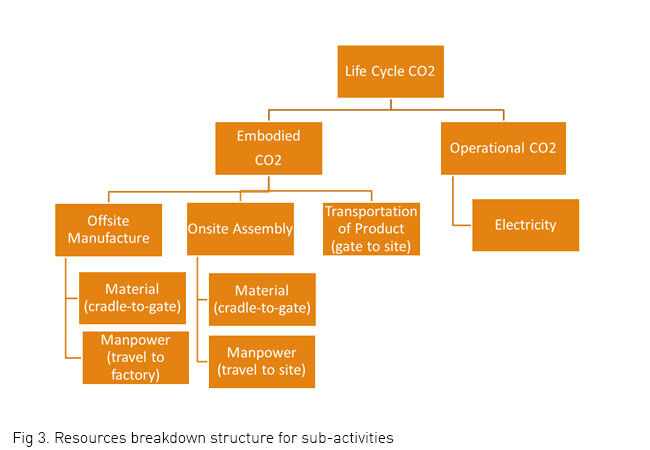

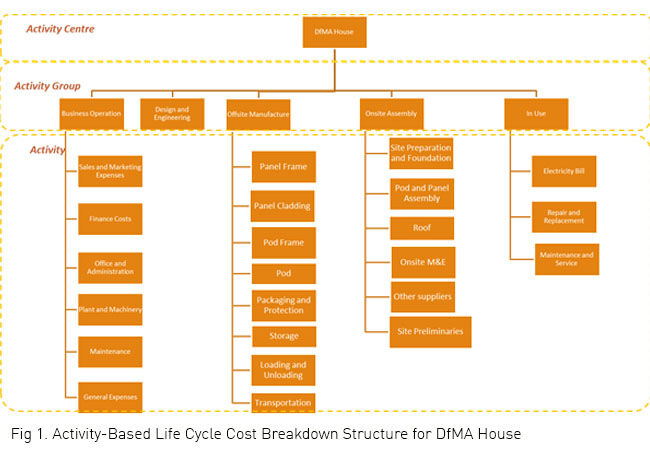

CO2 emissions model explained

The KBE tool provides an overall and breakdown of CO2 emissions of a DfMA house. The life cycle CO2 emissions is based on discrete models and broken down to a hierarchy of embodied CO2 and operational CO2 emissions (See Figure 3). Direct and indirect processes contributing to CO2 emissions are considered such as windows, vinyl flooring, steel frame, paint, materials for sub-activities and insulation. Other CO2 emissions included are fuel usage for employee’s car allowance, transportation for offsite products and consumption of electricity based on the family of five members profile defined by ESC over 60 years.

The CO2 emissions model excludes CO2 emissions from the processes of design and engineering, DfMA prototype testing, demolition, disposal, external business operations and during building in use other than electricity consumed over 60 years. Any additional materials, resources or products which are not defined for sub-activities are also excluded.

User-friendly interface for generating life cycle cost and CO2 emissions estimates

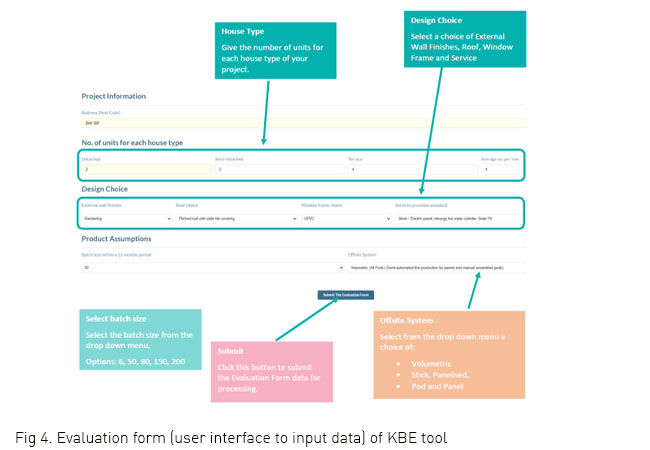

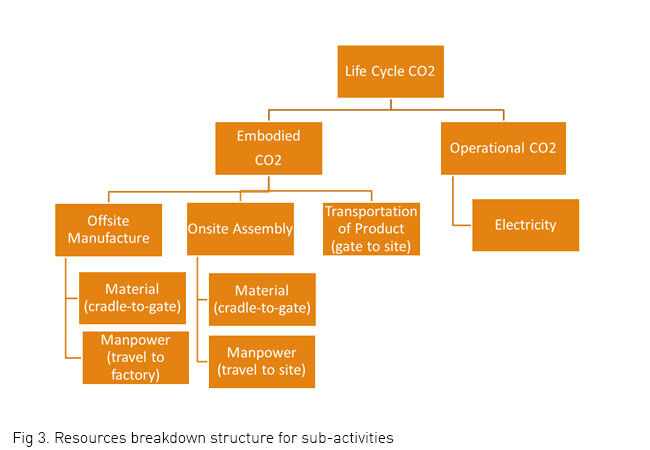

A user-friendly interface has been designed to generate the overall estimation and breakdowns of the life cycle cost and CO2 emissions automatically based on a set of evaluation assumption input as follow (See Figure 4):

- Project information including i) Address, ii) No. of units for each house type (Detached, Semi-detached and terrace), and iii) For terrace, if any, the average no. of terrace per row)

- Design choice including i) External wall finishes, ii) Roof choice, iii) Window frame choice and iv) Services provision standard

- Production assumptions including i) Batch size and ii) Offsite system choice.

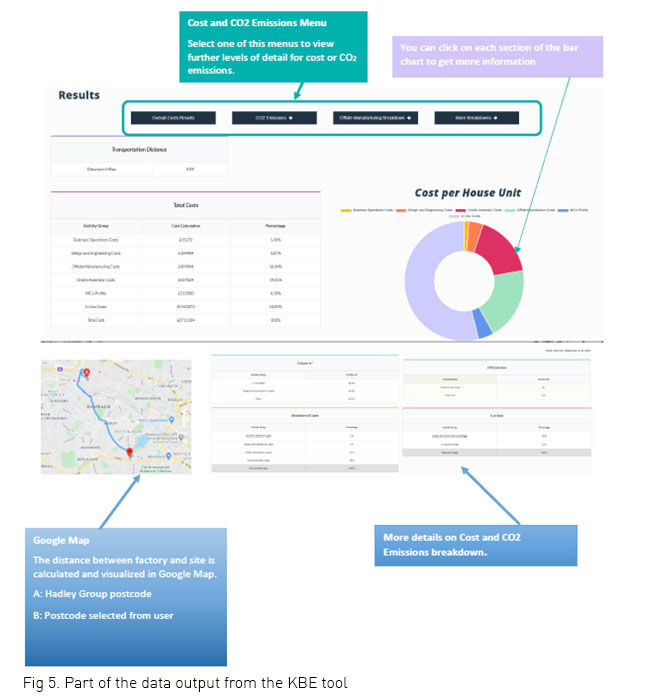

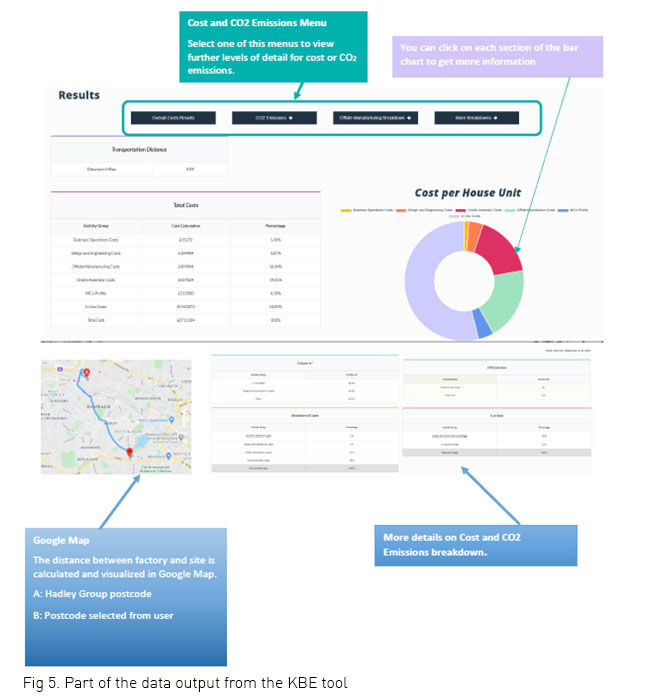

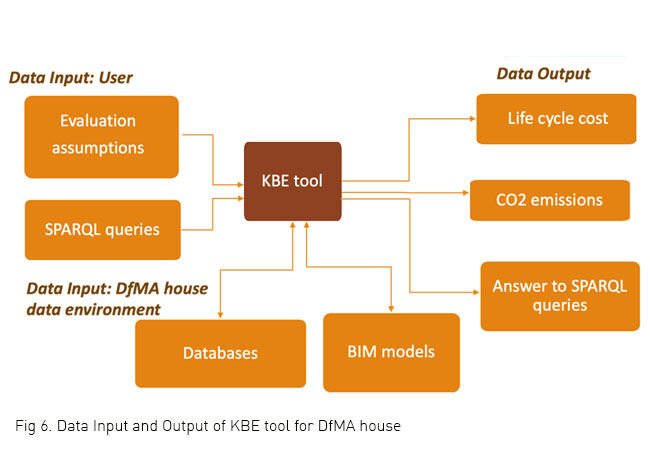

In turn, the life cycle costs and CO2 emissions will be generated (See Figure 5) based on the user input and data from various databases and BIM models (See Figure 6).

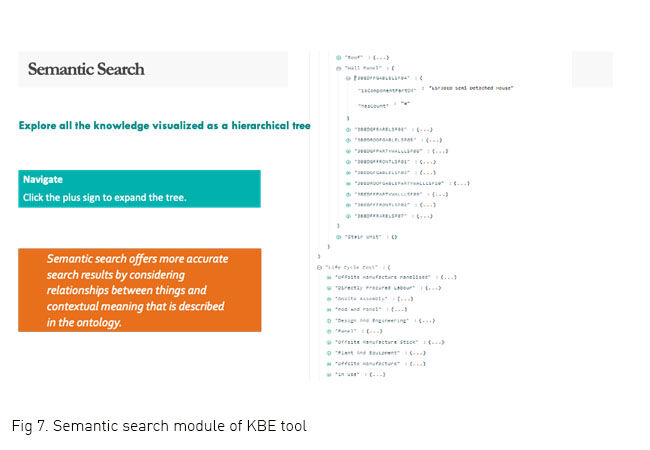

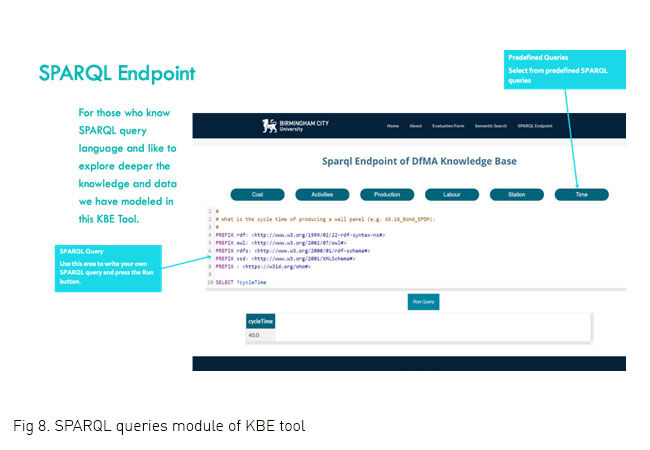

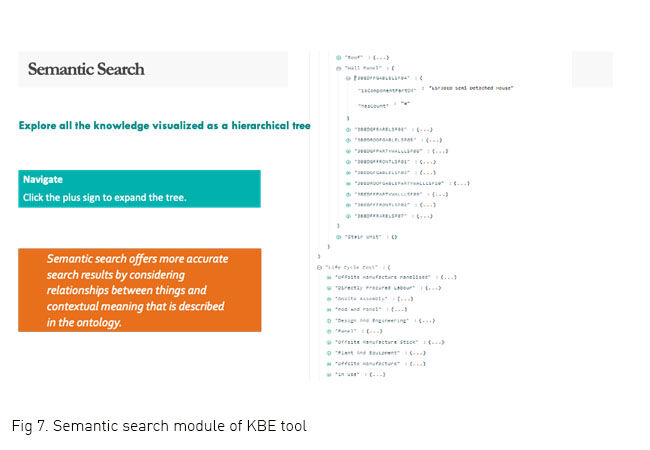

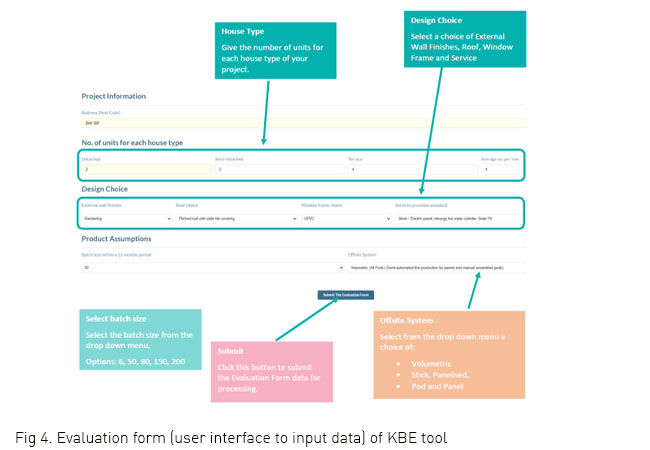

Additional modules for probing further knowledge of DfMA house

In addition, the user interface of the KBE tool contains a semantic search module (See Figure 7) and a SPARQL queries module (See Figure 8), which allows users who are competent with the use of data query languages to seek answers from the knowledge base to aid decision making.