Automotive Engineering with a Foundation Year - BEng (Hons)

Currently viewing course to start in 2024/25 Entry.

Study our Automotive Engineering BEng degree course and join one of the select UK Universities to take part in Formula Student events at Silverstone. Now is a fascinating time to study automotive engineering as you will have the chance to be at the forefront of developments within the industry....

- Level Foundation

- Study mode Full Time

- Location City Centre

- Award BEng (Hons)

- Start date September 2024

- Fees View course fees

- School School of Engineering and the Built Environment

- Faculty Faculty of Computing, Engineering and The Built Environment

This course is:

Open to International Students

Overview

Study our Automotive Engineering BEng degree course and join one of the select UK Universities to take part in Formula Student events at Silverstone.

Now is a fascinating time to study automotive engineering as you will have the chance to be at the forefront of developments within the industry. You will get to work in advanced automotive workshops and laboratories equipped with industry-standard equipment, as well as take advantage of more traditional office-based facilities.

We ensure you gain practical experience so that you are equipped to apply engineering science to real life situations.

What's covered in this course?

The Foundation Year course option enables you to study for our BEng (Hons) degree over an extended full-time duration of four years by including a Foundation Certificate (year one of four). The Foundation Certificate provides a broad study programme that underpins the follow-on degree. In order to progress to the next year of your degree, it is necessary to achieve a pass in all of the modules of the Foundation Certificate.

Our BEng (Hons) Automotive Engineering is designed to develop you as an engineer able to make a significant contribution to the industry as it goes through an important period of transition.

Our engineering courses focus on project-based activities, giving you lots of opportunity to work in teams on projects from design to implementation. This will give you practical experience of applying engineering science to real world problems, working in multidisciplinary teams to develop your interpersonal skills, and prepare you for a key aspect of modern engineering practice.

You will develop key technical skills, enhance your creative thinking and learn from industry experts, as well as gaining knowledge and application skills in stress analysis, drivetrain systems, suspension, body engineering, design and management.

Our course is structured so that its themes have a direct relevance to the industry’s current and expected future needs, and upon graduating you will have the intellectual, technical and personal qualities necessary to successfully implement new technologies.

Throughout your course you will benefit from our strong industry links with companies such as Jaguar LandRover, Norton Motorcycles or Continental Engineering Services.

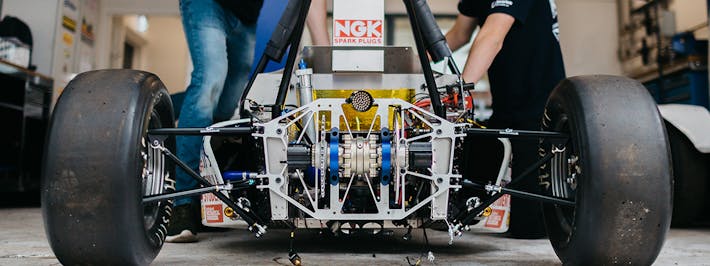

You will also have the opportunity to join our BCU Formula Student racing club, which designs and builds a racing car each July to race at an IMechE-sponsored event at Silverstone

Why Choose Us?

- Industrial placement year option - Gain desirable employability skills and work experience with the option of an industrial placement year, that will take place between your second and final year of the course.

- Employable graduates - Our graduates have progressed into roles with leading companies such as Jaguar Land Rover, Ford Motor Company and Aston Martin Lagonda Ltd.

- State-of-the-art facilities - You will be based at our Millennium Point campus in City Centre, where our facilities have undergone a £6.5 million investment with a new maker area, engineering labs/equipment and IT equipment to provide you with the very best learning experience.

- £1.1 million investment in new facilities from the IoT - The Institute of Technology (IoT) has invested in brand-new equipment and facilities, including an Electric Vehicle (EV) Test Rig, an Additive Manufacturing Machine (3D printer) and a material testing-split zone furnace - all industry grade technology that will advance your skills, making you more employable.

- Formula Student events at Silverstone - We are one of the select UK universities with access to take part in our international Institution of Mechanical Engineers (IMechE) Formula Student event at Silverstone. Read Thomas' story.

Open Days

Join us for an on-campus Open Day where you'll be able to meet us in person. Booking for the next event isn’t open yet. Register your interest below and we’ll email you as soon as booking goes live.

Next Open Day: 29 June 2024

Entry Requirements

These entry requirements apply for entry in 2024/25.

All required qualifications/grades must have been achieved and evidenced at the earliest opportunity after accepting an offer to help confirm admission and allow for on-time enrolment. This can also include other requirements, like a fee status form and relevant documents. Applicants can track their application and outstanding information requests through their BCU mySRS account.

80 UCAS tariff points

If you have a qualification that is not listed, please contact us.

Fees & How to Apply

UK students

Annual and modular tuition fees shown are applicable to the first year of study. The University reserves the right to increase fees for subsequent years of study in line with increases in inflation (capped at 5%) or to reflect changes in Government funding policies or changes agreed by Parliament. View fees for continuing students.

Award: BEng (Hons)

Starting: Sep 2024

- Mode

- Duration

- Fees

- Full Time

- 4 years

- £9,250 in 2024/25

- Apply via UCAS

International students

Annual and modular tuition fees shown are applicable to the first year of study. The University reserves the right to increase fees for subsequent years of study in line with increases in inflation (capped at 5%) or to reflect changes in Government funding policies or changes agreed by Parliament. View fees for continuing students.

Award: BEng (Hons)

Starting: Sep 2024

- Mode

- Duration

- Fees

- Full Time

- 4 years

- £16,085 in 2024/25

- Register interest

Guidance for UK students

UK students applying for most undergraduate degree courses in the UK will need to apply through UCAS.

The Universities and Colleges Admissions Service (UCAS) is a UK organisation responsible for managing applications to university and college.

Applying through UCAS

- Register with UCAS

- Login to UCAS and complete your details

- Select your course and write a personal statement

- Get a reference

- Pay your application fee and submit your application

Course in Depth

Foundation Year

In order to complete this course you must successfully complete all the following CORE modules (totalling 120 credits):

Mathematics plays a key role in establishing and grounding the professional skills of an engineer. Communicating the ideas of engineering is made both easier and harder by the use of mathematical language.

This module aims to help you become proficient at developing engineering models and arguments, and following them through to their logical conclusions, since application of these arguments has to include their interpretation both to and from the mathematical language.

The module aims to provide you with the knowledge and problem-solving skills in physical science to enable you to progress to the next module in the science theme, Engineering Science 2, and then on to the first year of an engineering degree.

This module aims to provide you with the practical and professional skills to enable you to progress to the next module in the practical theme, Practical Skills II, and then on to the first year of an engineering degree.

The theoretical aspects of physical science and maths are delivered in another theme of the foundation year. The Practical Skills modules sit alongside these and concentrate on the practical aspects to support your learning.

Mathematics plays a key role in establishing and grounding the professional skills of an engineer. Communicating the ideas of engineering is made both easier and harder by the use of mathematical language.

This module aims to help you become proficient at further developing engineering models and arguments, and following them through to their logical conclusions, since application of these arguments has to include their interpretation both to and from the mathematical language.

The module aims to provide you with the knowledge and problem-solving skills in physical science to enable you to progress to the first year of an engineering degree. The science theme contains the material normally encountered in an A level physics course which is relevant to entry to an engineering degree.

This module aims to provide the practical and professional skills to enable you to progress to the first year of an engineering degree. As the theoretical aspects of physical science and maths are delivered in another theme of the foundation year, the Practical Skills modules concentrate on the practical aspects.

First Year

In order to complete this course you must successfully complete all the following CORE modules (totalling 120 credits):

The module aims to provide the underpinning knowledge and problem solving skills in engineering science to enable you to progress to the next module in the theme, Engineering Principles II, and then on to the second year of a range of engineering degrees.

As the practical aspects of engineering science are delivered in another theme of the common first year, the Engineering Principles modules concentrate on the theoretical aspects. The subject material will be delivered in two coherent streams one of which contains predominantly mechanical science and the other contains predominantly electrical science.

Mathematics plays a key role in establishing and grounding the skills of an engineer, and the ability to communicate the ideas of engineering that are expected of an engineering graduates.

The primary aim of this module is to provide the fundamental mathematical knowledge and techniques needed in order to enable you to use and apply such mathematical techniques for the evaluation, analysis, modelling and solution of realistic engineering problems. Application of these data sets has to include their interpretation both to and from the mathematical language. In addition, this module will introduce students to mathematical modelling software package. This will be used to plot, annotate basic signals and write simple programs to compute mathematical problems.

This module will develop your ability to both work on and communicate engineering realities to a wider audience, at a professional standard.

The module aims to provide the professional skills needed to enable you to progress to the next stage of the practical theme, onto your next module: Integrated Engineering Project, and then into the second year of an engineering degree.

The subject material will be delivered in two core streams: a PC-based stream, which will include the use of software to support project planning, communication and analysis, and a project-space stream, where you have the opportunity to integrate learning from across all elements of the semester.

You will develop practical professional engineering skills; including skills required for conceiving, designing, implementing and operating (CDIO) engineering solutions.

This module will interact with modules in the other two themes in the first year, relying on the knowledge of mathematical techniques, and the theoretical underpinning of the engineering principles, design and professional skills.

The module aims to provide the underpinning knowledge and problem solving skills in engineering science to enable you to progress to the second year of a wide range of engineering degrees. As the practical aspects of engineering science are delivered in another theme of the common first year, the Engineering Principles modules concentrate on the theoretical aspects. The subject material will be delivered in two coherent streams one of which contains predominantly mechanical science and the other contains predominantly electrical science.

This module will focus on introducing and building on well-established techniques for mathematically modelling dynamic systems (systems of interest for engineering) for contextualised engineering applications. The module will include an introduction to sophisticated signal analysis technique, Fourier series which is used to transform time-domain signals into their frequency spectra. The module is structured to include a mixture of lectures, tutorials and PC-based laboratories. The lectures will formally introduce material, in tutorials students will work through questions with tutor. The PC laboratories will involve using mathematical modelling software packages to implement mathematical operations.

The module aims to provide the practical and professional skills to enable you to progress on to the second year of an engineering degree. As the theoretical aspects of physical science and maths are delivered in other themes of the first year, the Practical Skills modules concentrate on the practical aspects.

Second Year

In order to complete this course you must successfully complete all the following CORE modules (totalling 120 credits):

The module aims to provide a basic understanding of thermodynamic and fluid mechanic concepts. The understanding of the transfer of energy within thermodynamic systems and the incurred losses is vital to improve efficiencies of such systems, especially in light of growing environmental concerns and increased economic cost.

The knowledge and understanding will be gained through a balanced mixture of lectures and tutorials, whereby the learning will be supported by experiments.

The module introduces the mathematical concepts such as transform calculus and matrix theory used to solve systems of first and second order differential equations underpinning the engineering disciplines undertaken within the Faculty.

This provides you with the capability of modelling systems using both the transfer function and statespace paradigms. In particular, you will be able to model linear systems in continuous and discrete time as well as by frequency response methods.

Teaching and assessment will comprise not only traditional lectures and tutorials but also provide training in industry standard software for problem solving within coursework assessment.

The module provides you with the opportunity to learn about design, sustainable development, teamwork and communication whilst contributing towards real international development projects.

You will also gain the ability to communicate design ideas and practical details, to evaluate and apply both tangible and subjective feedback, and to conceive, design, implement and operate practical solutions to design opportunities.

It is anticipated that the project vehicle for this module will be the Engineers without Borders Design for People Challenge.

An interdisciplinary module, you will work with students from all fields of engineering to develop skills in engineering leadership and experience creating a purposeful vision and delivering on that vision. This will set the professional skills for business in context by combining your technical course-specific knowledge with professional skills. It is proposed that the vehicle to deliver this will be the biomimicry global design challenge.

This module develops your research skills, idea generation techniques, and ability to create CAD models and manufactured components.

You will also gain the ability to communicate design ideas and practical details, to evaluate and apply both tangible and subjective feedback, and to conceive, design, implement and operate practical solutions to design opportunities.

The Mechanical Science module applies the principles of engineering, physics, and materials science to the design, analysis, manufacture, and maintenance of mechanical systems and components. It is a branch of engineering that enables you to design, produce, and operate machinery. In keeping with the programme philosophy the module encourages learning through the practical application of fundamental mechanical science principles to the analysis and solution real world problems.

Final Year

In order to complete this course you must successfully complete all the following CORE modules (totalling 120 credits):

In the development cycle of new and existing components, processes and systems the use of computer analysis has a strong role to play. Reduced lead times can mean faster arrival at the market than competitors and therefore gaining an advantage. Engineers are at the centre of the development process and therefore require a good understanding of the key aspects of computer aided engineering (CAE).

The module presents the analysis, modelling and design of modern vehicle instrumentation and control systems. Industry-standard software will be used for the design and calibration of engine, vehicle, driveline and emissions after-treatment control systems using both time and frequency domain techniques.

Teaching and assessment will comprise not only use of industry standard software for the purposes of mathematical modelling, but also traditional lectures/tutorials assessed by examination.

Automobile design is experiencing a period of dynamic change. Alternative power-trains, fuels, materials, safety needs, and consumer demands for increased refinement will have a profound effect upon body architecture. The emphasis for this module will be on gaining insight into auto body structural behaviour and the relationship to the vehicle.

In times of consumer - and legislation-driven demand for increased fuel efficiency and reduced emissions of vehicles, the complexity in the development of future powertrains increases. A good understanding of powertrain sub-system behaviour is required to solve such complex systems. The module therefore aims to allow you to gain understanding of current technologies, but also an inside in emerging and future technologies to address the problems of future transportation. Formal lectures, tutorials, hands-on experience in labs and solving of problem based scenarios will enhance the learning process.

The purpose of the module is to enable you to undertake a sustained, in-depth and research-informed project exploring an area that is of personal interest to you. In agreement with your supervisor, you will decide upon your topic which will take the form of a practical outcome (artefact) with accompanying contextual material. The main consideration when choosing your topic is that it must be aligned to the programme you are studying, and you should consider the relevance of this topic to your future academic or professional development.

At this level, you will be expected to work independently but you will receive additional one-to-one support from your supervisor, who will be familiar with your chosen topic area. As you progress on the module, extra support will be available and this may take the form of group seminars, workshops and online materials that will help to develop your project.

Download course specification

Download nowThe Foundation Year modules focus on developing the key skills you will need to undertake a degree in engineering. In the first semester, you will study modules in Engineering Science, Mathematics for Engineers and Practical Skills. You will then explore these subjects in more depth in semester two.

Assessments will be carried out in a variety of formats, including written assignments, examinations, presentations and in-class testing. There will also be an emphasis on interactive learning, problem-solving tutorials and computer applications.

Intellectual skills, particularly analytical and problem solving skills are developed using a range of case-studies and problem / task based learning scenarios, promoting self-directed learning facilitated by problem-based learning centred upon industry practice and its inherent problems.

Assessment of such activities includes practical simulation and design exercises and individual and group projects, in addition to the methods mentioned above.

Employability

Our course is highly respected by the industry. Our graduates typically enter work with blue chip engineering companies, and are expected to progress to Chartered Engineer status.

When you study with us you’ll learn all the key aspects of automotive engineering that will help you to get a job and you’ll have the intellectual, technical and personal qualities needed to implement new technologies in the automotive engineering sector.

Wherever possible, we involve employers in curriculum planning and many of our lecturers come from and maintain their links with industry, ensuring they maintain their knowledge of the latest developments.

This strong partnership means you benefit throughout your time with us, because you have access to some of the world’s leading car companies, including Bentley, Morgan, Jaguar Land Rover and Ford.

It’s why many of our graduates have gone on to start very successful careers in a wide variety of roles in the industry, in areas ranging from development or design and performance engineering to automotive marketing.

Placements

We aim to have you employer-ready by the time you graduate, and as part of this commitment we encourage you to further enhance your career prospects by including an industrial placement in your course.

You will do your placement after the second year of study, which will extend the duration of your course to four years if you are studying on a full-time basis, and you’ll be supported throughout your time away.

Thanks to our excellent partnerships and strong relationships with industry, you could join the ranks of our students who have gained exceptionally high quality work experience at companies including Bentley.

International

Birmingham City University is a vibrant and multicultural university in the heart of a modern and diverse city. We welcome many international students every year – there are currently students from more than 80 countries among our student community.

The University is conveniently placed, with Birmingham International Airport nearby and first-rate transport connections to London and the rest of the UK.

Our international pages contain a wealth of information for international students who are considering applying to study here, including:

- Explore some of the good reasons why you should study here.

- Find out how to improve your language skills before starting your studies.

- Find all the information relevant to applicants from your country.

- Learn where to find financial support for your studies.

Facilities & Staff

Our Facilities

The Department of Engineering provides the perfect setting for practical work with modern-day teaching and learning facilities. We pride ourselves on equipping our students with the skill set that they need not only working on industry standard equipment, but having industrial links, which set them up perfectly for a career in engineering.

We are currently undertaking a £400 million investment programme in our facilities, including a major expansion of our City Centre Campus. As part of this, our facilities in Millennium Point have undergone a £6.5 million investment to include a new maker area, engineering labs and equipment.

We have invested in industry-standard facilities to support the practice-based elements of our Engineering courses and give students as much practical learning as possible, to prepare for industry placements and job opportunities after graduation. Students have access to our facilities during classes, and can book out of class sessions with our specialist technicians.

We are a partner of the Greater Birmingham and Solihull Institute of Technology (GBSIoT) and have secured £1.1 million of government funding for investment in brand-new equipment and facilities. Funding of £808,000 from the Department for Education has supported our development of an Electric Vehicle (EV) Test Rig, an Additive Manufacturing Machine (3D printer) and a material testing-split zone furnace.

The IoT has enabled procurement of new technologies for material testing, electronics prototyping and production and 3D scanning to compliment computer aided design for manufacture

Our staff

Man-Fai Yau

Senior Lecturer

Man-Fai has 10 years' experience in private sector industry, two years' with a Knowledge Transfer Partnership (KTP) and 12 years' university lecturing.

More about Man-FaiFlorimond Gueniat

Senior Lecturer in Automotive Engineering and Course Leader for MSc Automotive Engineering

Florimond Guéniat has a PhD in fluid mechanics and computer science from Univ. Paris Sud. He then spent two years in the Department of Mathematics, at Florida State University researching on the control of fluid flows.

More about FlorimondDr Richard Cornish

Senior Lecturer

Dr Richard Cornish is an Automotive Engineer with a wide experience of automotive research and development, especially developing test methods and models to capture new practical knowledge and theoretical insights. His areas of expertise include simulation, test, measurement, durability, fatigue and product perception, and he has worked on CAS,...

More about RichardJens Lahr

Senior Lecturer for Automotive and Mechanical Engineering

Jens is a senior lecturer for BEng/MEng Automotive and BEng/MEng Mechanical Engineering. His teaching includes the subjects of Finite Element Analysis, Structural Analysis and Powertrain Performance. He helps and supports practice-based learning (CDIO).

More about JensDr. Md Mostafizur Rahman

Senior Lecturer

Dr. Rahman is a Senior Lecturer at the School of Engineering and Built Environment, Birmingham City University. He got his Ph.D. from Queensland University Technology(QUT), Australia in 2015. He then worked as a Postdoctoral Researcher at QUT and the University of Cambridge respectively in collaborative research projects with leading industry...

More about Mostafizur